ASSEMBLY AND DISASSEMBLY

ATIENTION: DO NOT use a compressed air source (i.e., automotive tire air compressor) to inflate boat.

Overinflation through the use of compressed air may result in ruptured seams and/or bulkheads.

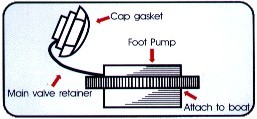

ASSEMBLY

1. Remove any sharp objects from the area where boat will be assembled and inflated.

2. Unfold and spread boat out flat.

3. Attach the valves in their proper place. Check that the cap gasket is in place. Attach valve retainer to each valve.

4. When using the boat for the first time, fully inflate boat by attaching foot pump to each of the valves, one at a time, and pump air to maintain a balance of pressure between chambers until fully inflated.

When the boat is fully inflated, unscrew valves and continue with assembly.

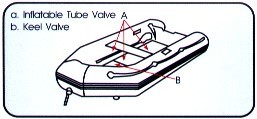

NOTE: Do not inflate keel until floor boards are installed.

5. If boat has been previously inflated, attach foot pump to each valve, one at a time, and add air to each chamber to 1/2 the capacity of each chamber.

ASSEMBLY of aluminum or plywood deck

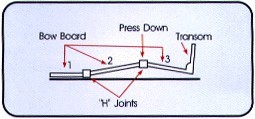

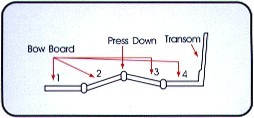

FLOOR AND “H”-JOINT ASSEMBLY FOR 230cm to 300cm

NOTE: When installing floor boards, identifying numbers of boards must face up.

1. Insert #1 floor board in bow of boat and attach “H”-Joint.

NOTE: Each “H”-Joint should be installed with larger flat side facing up.

2. Insert #3 floor board into transom of the boat.

3. Insert #2 floor board into “H”-Joint attached to #1 floor board.

4. Insert “H”-Joint between #2 and #3.Press floor board until flat.

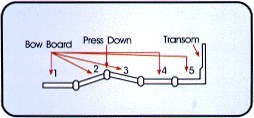

FLOOR ASSEMBLY FOR THE 330.360.380

NOTE: Identify numbers on floor boards face up.

1. Insert #1 floor board in the bow of boat.

2. Insert #4 floor board in transom of the boat.

3. Insert #2 floor board into #1 floor board.

4. Insert #3 floor board into #2 and #4 floor boards

and press down until flat.

FLOOR ASSEMBLY FOR THE 410.430.470

NOTE: Identify numbers on floor boards face up.

1. Insert #1 and #2 can be made as one set .

2. Insert #5 and floor board in transom of the boat.

3. Insert #3 floor board into #2 floor board.

4. Insert #4 floor board into #3 and #5 floor boards and press down.

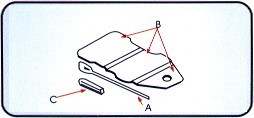

SIDE JOINER ASSEMBLY

1. Slide oar(a) under bottom to raise floor boards (b) from surface.

Attach side joiner. Repeat procedure on opposite side of boat.

2. Install seat.

3. Fully inflate boat by attaching foot pump to each of the valves,while maintaining a balance of air between air chambers.

4. Inflate keel and install valve caps.

DISASSEMBLY

1. Unscrew all air valves to deflate boat.

2. Remove seat.

3. Remove side joiners from floor boards.

4. Raise the middle floor and detach from “H”-Joints (230.265.300).

Remove floor boards. Remove bow and transom boards last.

5. Put floor boards, ”H”-Joints, side joiners and oars in carrying bag.

6. Use foot pump as a suction device, remove excess air from each chamber.

7. With bottom side facing down, tuck gunwale tubes into boat. Roll boat from either end and place in carrying bag along with pump and hose.

Qingdao Colton Yacht Co.,Ltd Factory address: Developed zone, Laixi District, Qingdao,China Office address: Baoli building,Jinshui road, Licang district, Qingdao,China

Qingdao Colton Yacht Co.,Ltd Factory address: Developed zone, Laixi District, Qingdao,China Office address: Baoli building,Jinshui road, Licang district, Qingdao,China +8615165275783

+8615165275783 sales@coltonyacht.com

sales@coltonyacht.com IPv6 network supported

IPv6 network supported